ISO 9001:2015

Engineering

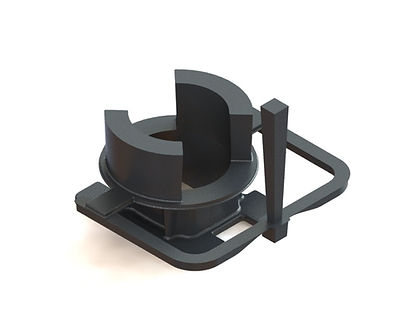

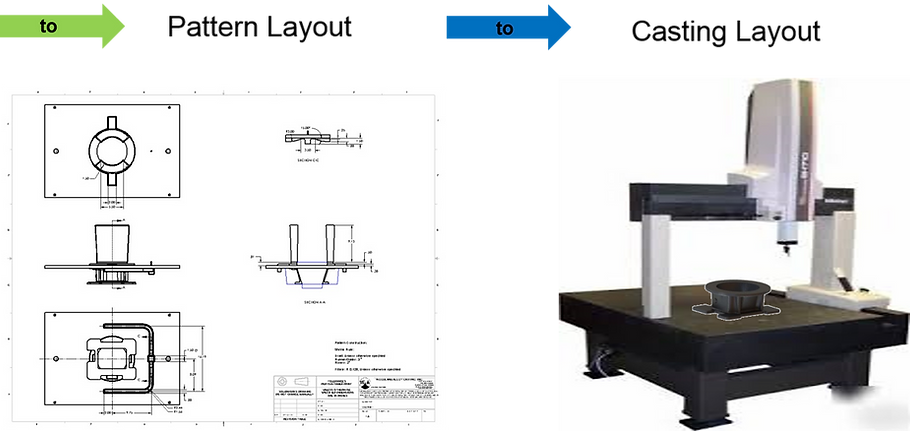

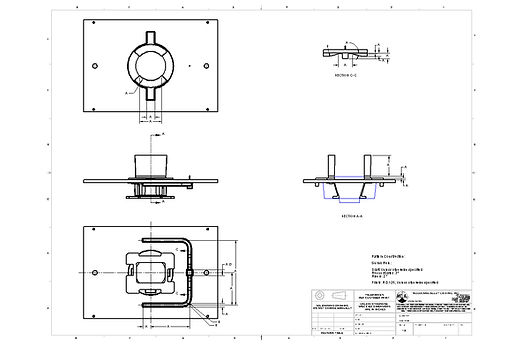

Woodland’s engineering team has access to the latest software connecting your CAD model to our 3D modeling and casting simulation through the CMM ensuring the quality part you are looking for.

Engineering info

With continuous improvement always in mind, Woodland has recently upgraded our engineering systems software to meet our customers growing needs. Advanced 3D modeling tools allow us to integrate your model from a variety of files into our production process. This system is designed to easily manipulate the geometry of 3D models to achieve design and production capabilities. Furthering our advancements, we have invested in solidification simulation software giving us the ability to engineer the very best part. Solidification software allows the engineer to run multiple variations of a product design looking for potential casting issues, such as porosity, shrink and cold shuts. Finally, Woodland added a Coordinate Measuring Machine (CMM), where we use your approved 3D model to measure against and ensure a dimensionally accurate casting.